After years of operation, a soft drink bottling facility in Honolulu, HI was experiencing signs of pipe failure in their plumbing system. Blocks and leaks caused by the deteriorating pipe network were impacting daily work and had rendered one bathroom in the facility completely unusable for the employees.

The extensive pipe network was located under concrete and spanned the entire production floor, making pipe replacement impossible to complete without prolonged disruption to the operation. They also needed to ensure that any product used for repair was safe for usage in food and beverage production. They opted to rehabilitate the pipes using NuFlow’s cured in place pipe lining.

A NuFlow Certified Contractor performed a camera inspection and cleaned each section of the pipe network. In some areas the pipes were so badly corroded that it resulted in a complete void in the bottom half of the pipe. Other areas were not as severe, but still showed signs of deterioration with potential for future problems. They opted to line the entire system to repair the existing damage and prevent future pipe failure.

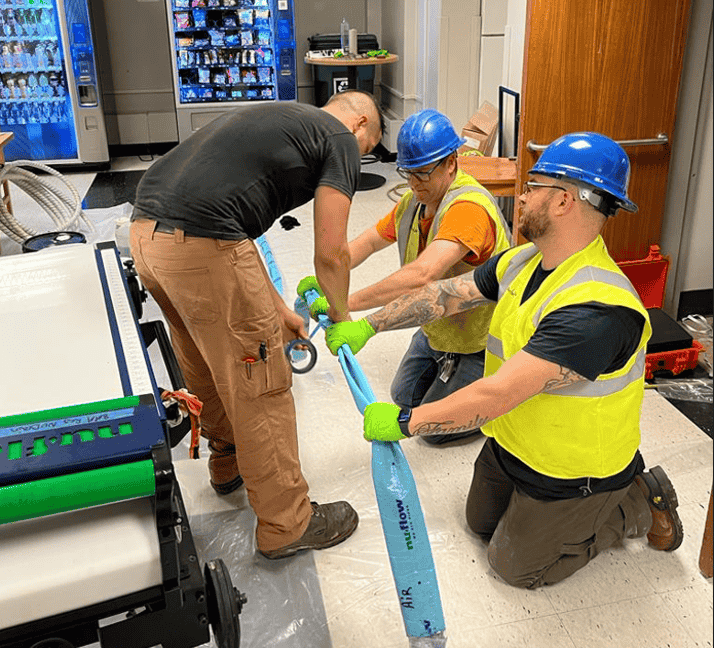

The NuDrain CIPP system uses a durable felt liner combined with a two-part 100% solids epoxy. The liner is saturated with epoxy resin and pushed/pulled into place with an inflatable bladder to expand the liner into the walls of the existing pipe. The epoxy then cures in place to create a structural pipe within the old pipe. NuFlow’s 100% solids epoxy is free of VOCs (Volatile Organic Compounds) or styrene making the usage acceptable even in food and beverage production facilities.

NuFlow worked with the customer to ensure the bottling production would not be impacted through the pipe rehabilitation process. Utilizing existing cleanouts and two predetermined 4’ x 4’ trenches that would not impact the machinery or sanitation requirements on the production floor, the installer had access to repair the entire pipe network. The precision push/pull in place installation method allowed the installer to verify tie-in locations for lateral connections and reinstatement using a CCTV camera. The entire project was completed over a few weekends, working Friday to Sunday evenings, to allow full operation of the facility throughout the week.

Over the course of the project, NuFlow rehabilitated 180’ of 4” and 6” cast iron sanitation pipes without disrupting production of the bottling plant. After 10 years, the bottling facility is still in production.