NuCure Cold Cure UV

The original true cold cure UV LED

NuFlow Technologies, a leader in the small-diameter CIPP lining market for over 20 years, continues to innovate in CIPP technology and expand its global network of Certified Contractors. NuFlow’s NuCure Cold Cure UV (CCUV) represents an evolutionary leap in UV cured pipe lining technology. Combining low-voltage UV lighting with our proprietary cold cure UV resins, NuCure CCUV sets a new standard in light curing technology for UV cured pipe lining.

This UV cured pipe lining technology minimizes the risk of error by activating liners in place, significantly reducing curing time, and offering flexibility for contractors to wet out on or off-site. NuFlow’s NuCure CCUV brings industry-leading performance to the UV cured pipe lining market at a game-changing price, making it a preferred choice for modern pipe rehabilitation projects.

NuCure CCUV's approach to UV cured pipe lining ensures a faster, more reliable, and efficient pipe rehabilitation process, aligning with the needs of today's fast-paced construction and maintenance projects. By adopting this advanced UV cured pipe lining solution, contractors can deliver superior quality and durabiity in their pipe repair and rehabilitation services.

What Should I Know About UV Curing?

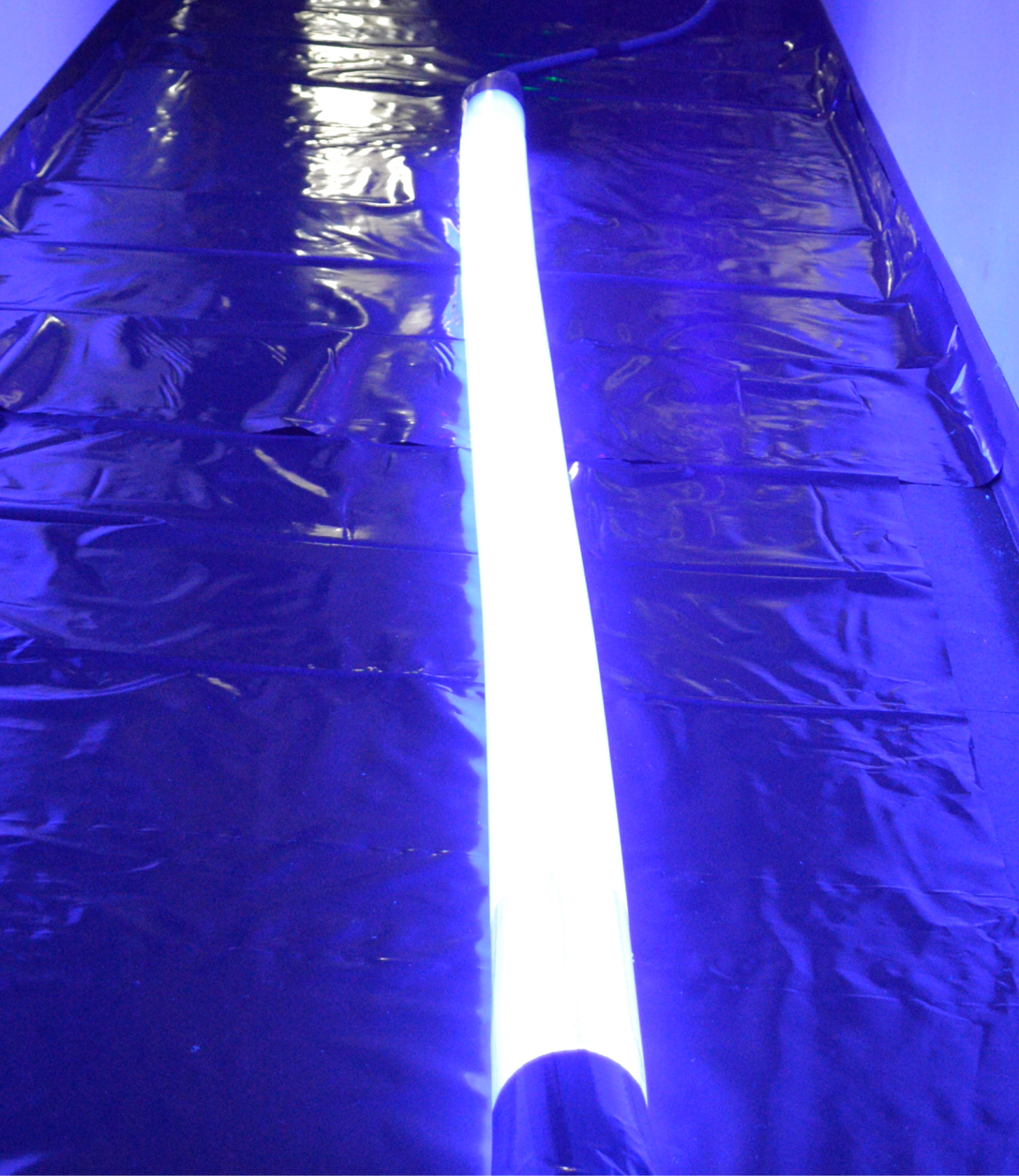

The UV cold light LEDs and Precision PIP (push or pull-in-place) technology minimizes the risk of error by activating liners in place, significantly reducing time for curing, and allowing the contractor to wet-out on or off-site. NuFlow’s NuCure CCUV brings industry leading performance at a game changing price.

UV liners cure much faster than the alternative curing methods. Whereas an ambient cure requires 8 to 10 hours of processing time and thermal curing requires 2 hours, UV curing can be completed in as little as 10 minutes. This allows operators to focus on the quality of the rehabilitation without the stress of racing against the clock.

Faster curing time results in less resin slumping for a more consistent wall thickness and less resin bleed-off, wash out, emulsification, or other adverse impacts from site conditions prior to curing.

Resins used for UV curing have the same backbone as thermal curing resins; the key difference is the curing initiator. With the end-product equivalently the same, UV curing offers significant advantages by reducing potential disruption factors and increasing efficiency

UV initiated resins do not require refrigeration for shipping and storage. Inventory management is simpler, and pre-mixed materials can be purchased at bulk discounts and used over time. When advantageous, UV cured liners can be pre-wet out and delivered to the jobsite ready for installation.

UV curing equipment generally requires less maintenance than hot water or steam generators, which can require frequent flushing and periodic descaling. UV equipment does not have comparable safety concerns and costs less than thermal curing equipment.

Because the resin is activated in-place with UV light exposure, UV cured resins provide indefinite “pot life” (working time). This reduces risks from unforeseen site conditions and permits crews time to make adjustments if needed.

Varying temperature conditions do not significantly alter the required curing times for UV cured resins. There is no need to adjust the resin mixture or the curing schedule for extreme hot or cold site conditions. In addition, UV curing requires substantially less expertise because there are fewer variables impacting the quality of the liner.

UV cured liners have a reliably dense cure that eliminates uncertainties such as flexural modulus, abrasion resistance, corrosion resistance, leak tightness, etc. This ensures a consistent life-cycle performance and consistently satisfied end-users.

What makes NuFlow’s NuCure the preferred UV cured solution?

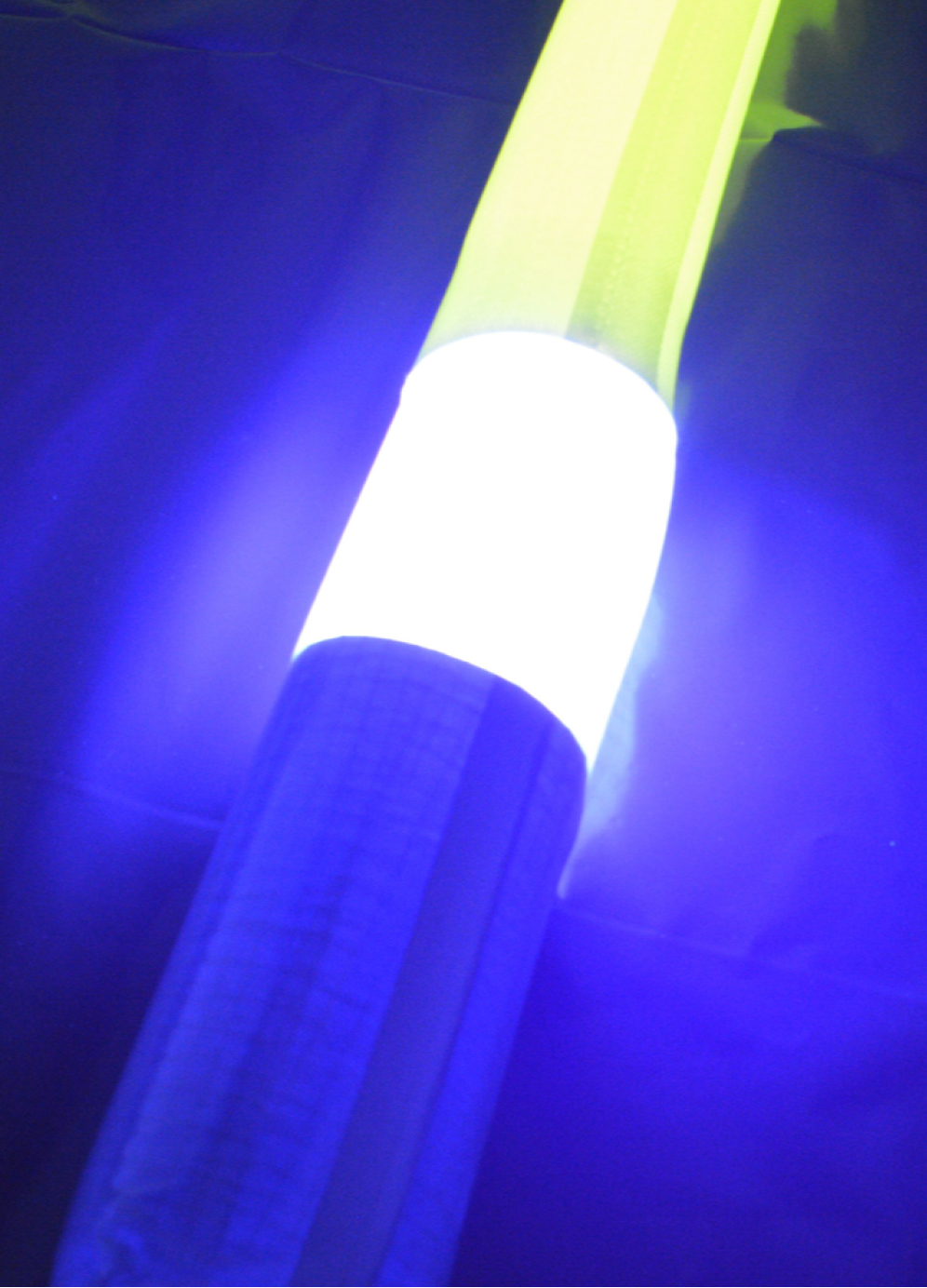

Proprietary Double Helix™ Light Core Assembly

NuFlow’s unique Double Helix CCUV technology and dual power supplies ensures the light will penetrate the entire length and depth of the liner, from end to end.

- The Double Helix design entwines multiple LED light ropes into 3’, 10’, and 30’ CCUV light cores for curing of NuFlow’s CCUV resins.

- Extensive R&D on optical power density and dual power supplies ensures complete and rapid curing of the full liner, end to end.

- The double rope creates redundancy to complete the cure in the event of damage to any of the integrated LED light ropes.

- The Double Helix CCUV Light Core is inserted into the translucent inflation bladder and is connected by an umbilical to the NuCure Control Unit for installation.

- Precision PIP installation methods enable NuCure CCUV to achieve superior liner insertion without cumbersome inversion equipment or complex robotics.

- Robust, custom-designed umbilical adaptor end provides a secure connection and reduces the chance of damage.

- LED light emitters significantly lower thermal emissions and are more efficient than phosphorous bulbs used in large diameter light trains.

The reduced thermal emissions are a key factor eliminating the need for additional equipment and footprint such as high CFM ventilation and airdrying.

Cold Cure Resin

Technology

NuFlow’s NuCure CCUV leverages its proprietary cold cure resin technology that has many advantages over the legacy CIPP resins:

- Shelf-stable for a minimum of 10 months; wet-out months in advance. Just recalibrate and you’re good to go.

- Long pot life together with exceptionally fast UV cure times.

- Zero VOC avoiding nuisance odors and resident concerns at the job site.

- Cures with a low-peak exothermic temperature (below 150° F) and achieve an extraordinarily high Heat Deflection Temperature [HDT], allowing for use with elevated temperature flows.

- Cures densely within 10 to 20 minutes (based on I.D.), speeding required installation times and limiting the duration of thermal energy release.

- Low temperatures and durations mean NuCure CCUV CIPP liners can be installed within thin-walled plastic pipes, which could not be lined with other CIPP technologies.

NuCure GRP Liner Tubes

- Resin Protection System ™ protects the resin from sunlight or UV exposure; work without fear of premature curing.

- NuFlow’s NuCure GRP Liner Tubes have been engineered for performance.

- Seamless, radially expandable, ECR, fiberglass tubes engineered to generously conform to bends and even size transitions.

- Precision PIP for reliably accurate placement at lower risk.

- ECR glass for inherent corrosion resistance.

- Fiberglass reinforcement provides a thin wall, high strength structure to avoid flow loss.

- The Resin Protection System, consists of an integral PU outer coating, which offers high thermal stability and a removable inner calibration bladder that assists with containing and evenly distributing the resin; protecting the resin from excessive bleed-out, blow-out, wash-out, emulsification; and protecting against resin slugs.

- Also available as Wyes and Tees for lining branch connections, allowing for the full structural rehabilitation of a piping system.

NuCure CCUV Demo

Backed by NuFlow

Equipment and liners are backed by NuFlow’s Manufacturer’s Defect Warranty, and NuFlow also supports customers with our North American Equipment Maintenance Center.

JOIN

TODAY!

Begin the path to new expertise, product offerings, and revenue streams. NuFlow technicians are highly-qualified educators and can offer the industry expertise, guidance, and resources to help you start installing state-of-the-art NuFlow products in no time.

Let's Get Started

"*" indicates required fields