Brewers at a local craft brewery were troubled when the pipes in their brand-new production facility were failing. The brewery, built in 2018, was specially designed to fit their needs and outfitted with fresh PVC pipes. The pipe network was located under a concrete slab with rows of brew kettles and fermentation tanks, so the brewers needed a solution to fix the pipe issues without tearing up the entire brewery and disrupting production. They turned to CPR, a NuFlow Certified Contractor, to solve the problem.

When CPR performed a camera inspection of the pipe infrastructure, they found multiple breaks in the joints on the main line of the system. The extreme temperatures used during the brewing process caused the breaks, resulting in overflow and loss of materials. The CPR team recommended lining the pipes to fix the problem with the joints and prevent any future issues from the constant high temperatures. While the customer was eager to fix the problem, they had concerns about the process. They did not want to shut down brewery production, wanted to ensure the product could withstand the temperatures regularly used in the brewing process, was resistant to the chemicals used in the cleaning process, and wouldn’t affect the quality of the beer. CPR leaned on the technical support team at NuFlow to address the concerns.

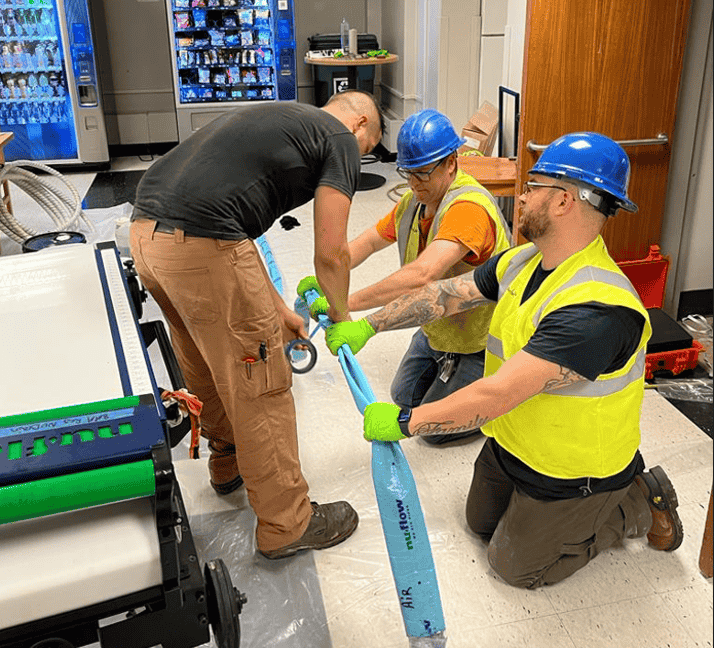

The brewers provided the specifics that were required in the brewing process – a consistent heat of 240-degrees and a list of chemicals used during cleaning. With all the information gathered, NuFlow recommended using NuCure Cold Cure UV technology. Grant Whittle, NuFlow’s Technical Director explained, “The dense cure of the NuCure system results in exceptionally high heat deflection temperature (HDT), enabling the NuCure CCUV liners to be utilized in very high temperature applications. It is a perfect application at the brewery to combat extreme temperature fluctuations. The UV system’s ability to tolerate high temperatures opens new markets that other lining systems cannot adequately serve.” NuFlow also confirmed the safety information and chemical analysis of the UV system, so the customer was confident it was the right choice. As a bonus, the NuCure Cold Cure UV system cures within 10 minutes and allows for immediate reinstatement of the laterals, cutting the production time of the project in half.