NuFlow’s Vertical and Horizontal Connection Liners (VHCL) allow you to line entire pipe infrastructure - including wye’s and tees. Launch from upstream or downstream. No need to “skip the fitting”!

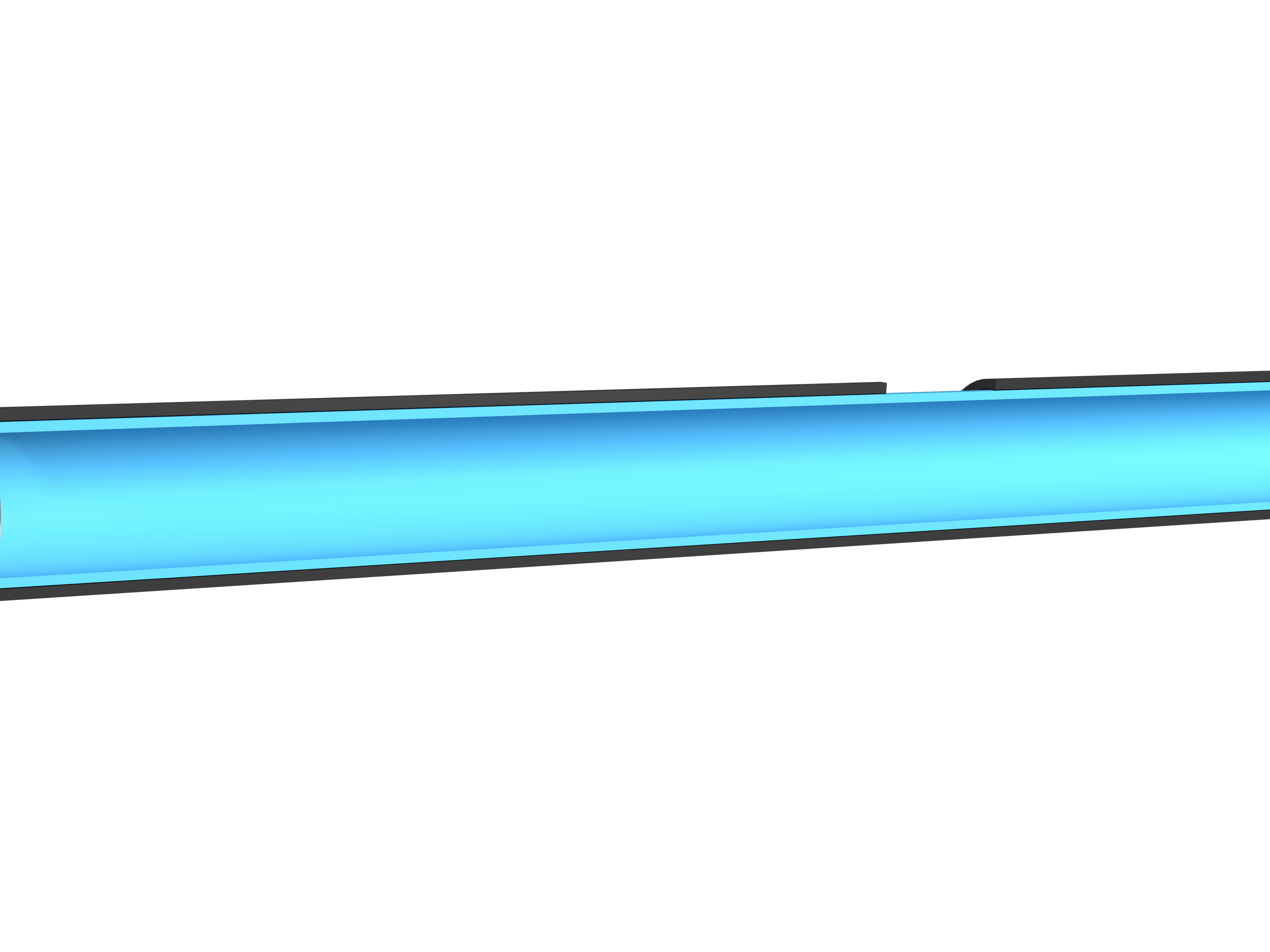

NuDrain's Cured In Place Pipe-lining technology (CIPP) empowers NuFlow certified contractors to structurally rehabilitate the pipe network outside, beneath, and within the building envelope. This innovative Cured In Place Pipe-lining solution acts as a stand-alone pipe within a pipe, offering a robust and reliable alternative to traditional pipe replacement methods.

This system is capable of handling networks ranging from 1 1/2 inches to 12 inches in diameter, with custom Cured In Place Pipe-lining sizes available up to 96 inches, NuDrain is versatile and adaptable. This Cured In Place Pipe-lining system can be used in a wide variety of systems, including mains, horizontal laterals, vertical stacks, roof drains, as well as sanitary drain, waste, and vent systems. The thin epoxy liner, a critical component of the Cured In Place Pipe-lining process, is installed to the pipe's interior. This liner seals and protects the system from further deterioration, dramatically extending the life of the piping system.

NuDrain, a leading solution in the Cured In Place Pipe-lining sector, is the answer to solving and extending the useful lifespan of non-pressurized mechanical systems. Through its extensive network of licensees, NuFlow has successfully rehabilitated millions of feet of failing pipe systems using this advanced Cured In Place Pipe-lining technology.

1

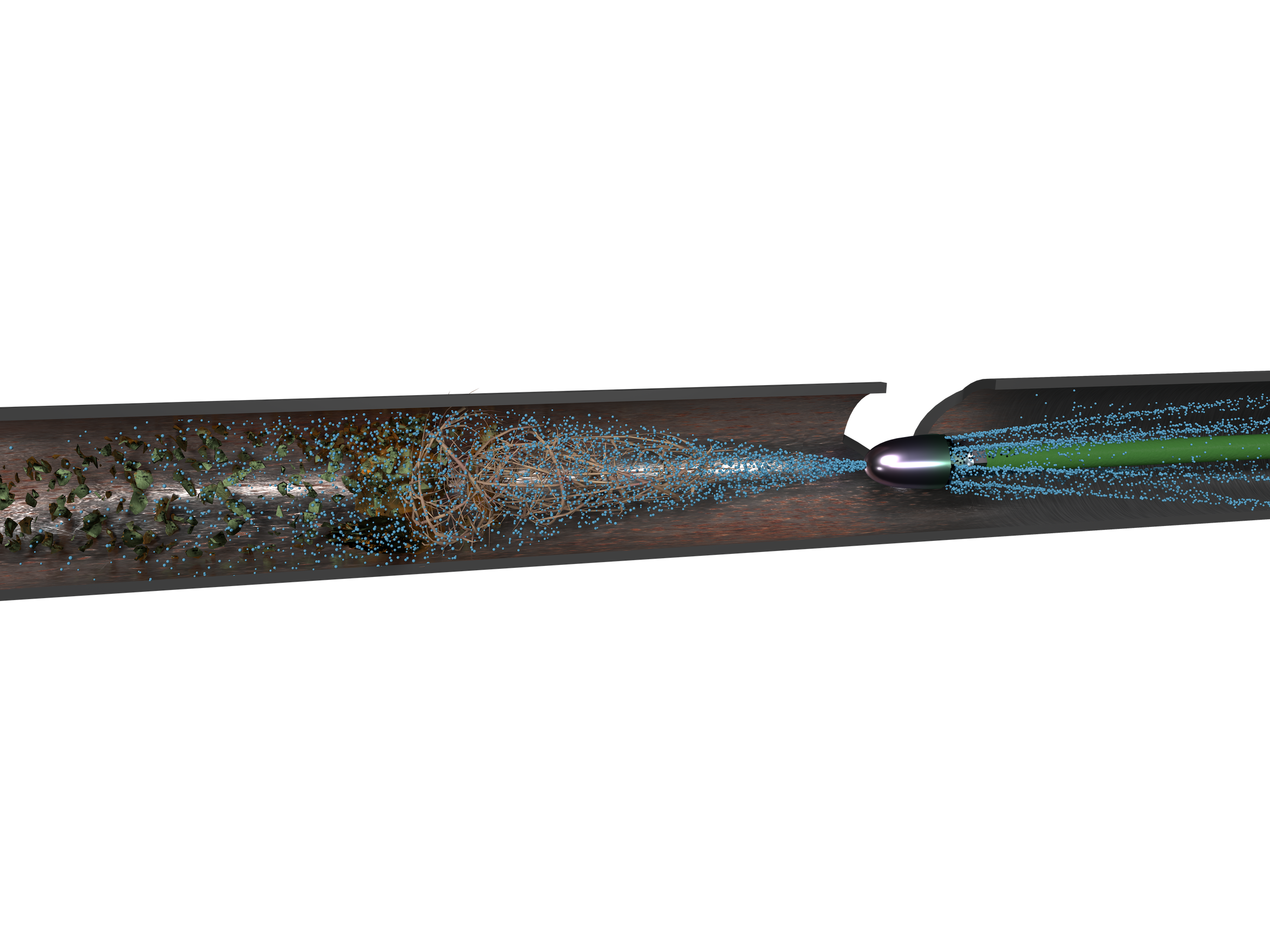

Blocked, root-intruded and corroded pipes are cleaned with tools and processes appropriate to the situation.

2

A flexible, epoxy saturated liner is pushed or pulled into place through existing access points. An internal bladder is inflated, pressing the liner against the pipe wall.

3

The resin cures, often in a matter of minutes, and the bladder is deflated and removed, leaving behind a clean, seamless “pipe within a pipe."

- Can be installed injunctions, bends, horizontal and/or vertical pipes in one complete application

- Can be installed in the pipe with multiple bends, elbows, branches, and changes in pipe diameter

- Improves water flow

- Start and stop lining at any point within the pipe to give greater flexibility with sectional lining

- Meets or exceeds ASTMD790, D638, and D543 Standards

- Life expectancy: 50+ years

Can Be Used In

- Host pipes consisting of clay, concrete, metal, iron, steel, plastic and fiberglass

- Residential, commercial and industrial applications

- Sanitary drain pipes

- Roof drain systems

- Vertical sanitary systems

- Water main and storm drain systems

The Precision Push- or Pull-in-Place Advantage

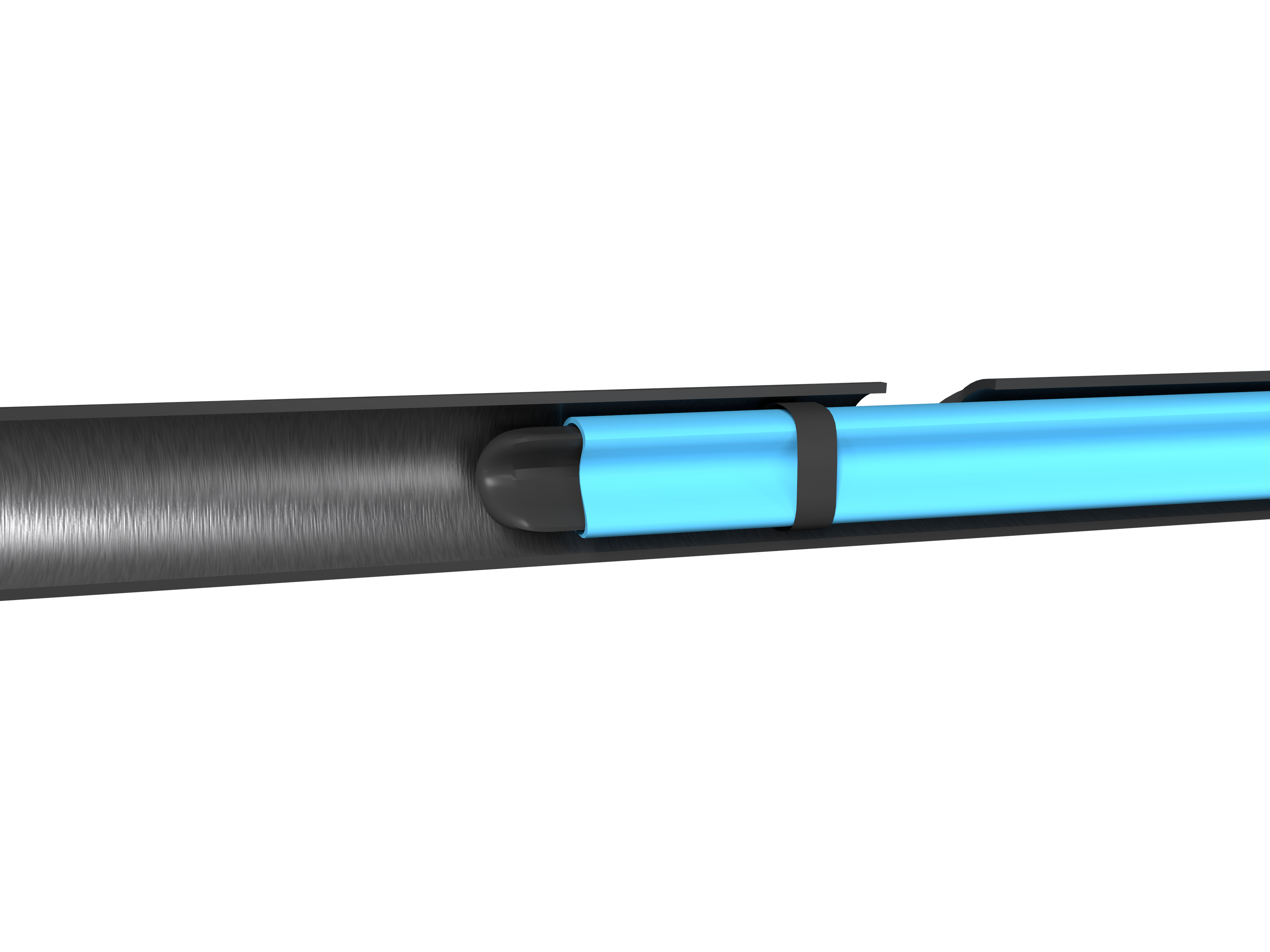

Precision PIP application starts with a felt liner soaked in epoxy and pulled into place through the system. When the felt liner is in place, a rubber bladder is expanded internally using air pressure to help the epoxy adhere to the interior of the pipe.

- More accurate placement for inside the building applications.

- Launch from any existing access point - clean-out, toilet riser, vent

- Pull from any man-hole, two-way clean-out, or directional clean-out

- Push System allows you to push the liner into place with no downstream access.

A pull-in-place application can be used through 45° and 90° angles whereas inversion applications cannot. The pull-in-place application also allows you to “start and stop” so you can line-specific pipe sections rather than the entire length. For more details visit our blog post Why NuFLow Preferred.

Pipe Lining Process

Inspecting

Installing our pipe lining product begins with inspecting the condition of the pipe system through use of CCTV camera inspection.

Measuring

Once the pipes are inspected and measured the problem areas are accurately mapped. The internal pipe is then cleaned of buildup and corrosion so that the liner can make a mechanical bond to the inside walls of the host pipe. After cleaning, the pipe system measurements are transferred to the lining material and the segment is built. This ensures that the liner is accurately measured for installation.

Installation

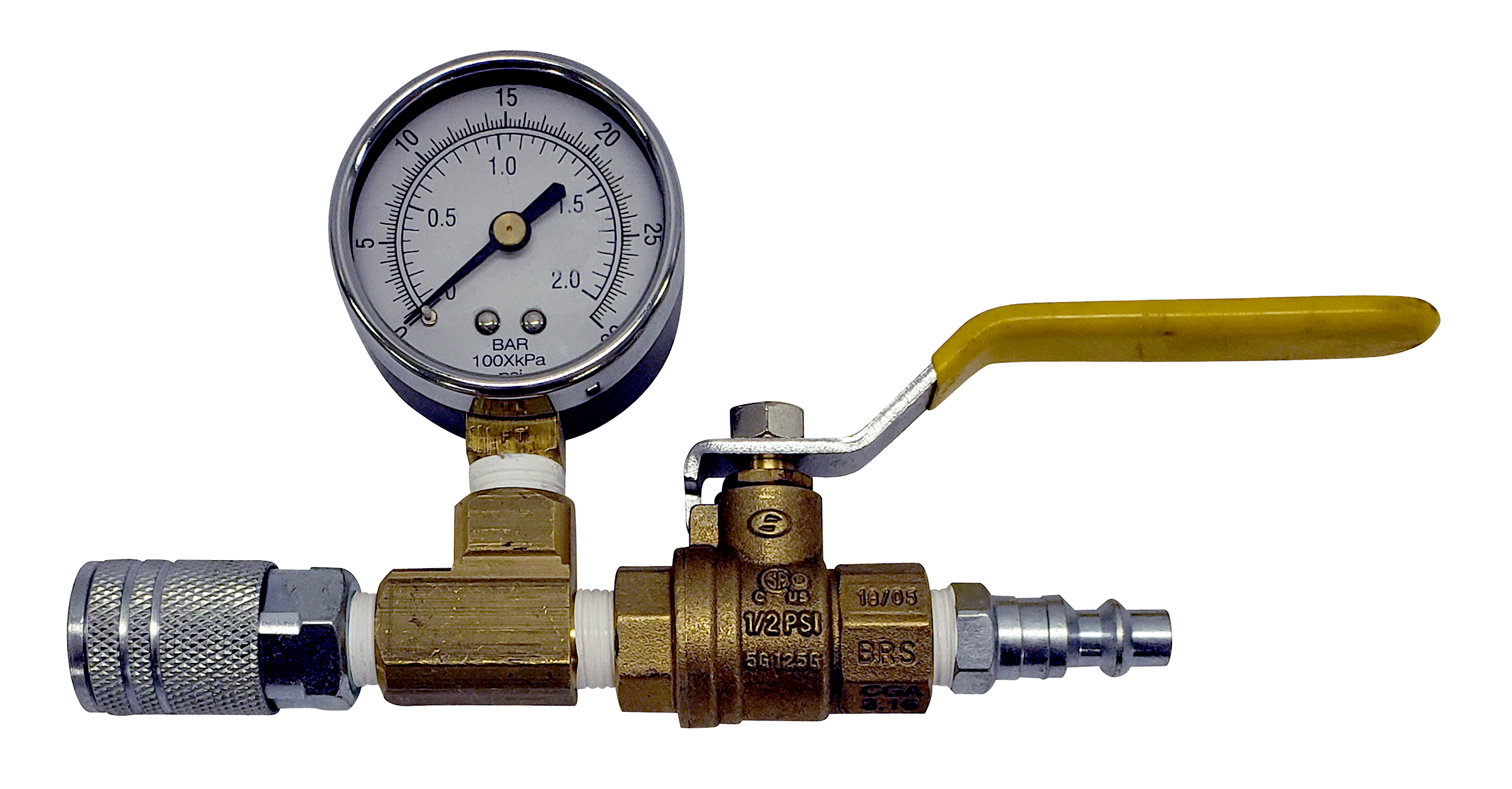

Once the liner is built to length, a calibrated air pressure test ensures the liner will install properly. A two-part, 100 percent solids epoxy resin is measured, thoroughly mixed and poured into the liner. A calibrated roller is then used to saturate the felt liner, which is then folded and temporarily taped together. This reduces the profile of the repair segment allowing for ease of installation into even the most intricate pipe networks. The epoxy saturated liner is then pulled into place through an existing access point such as a cleanout, a toilet riser, a roof vent, or other access points already existing in the system.

liner placement

Once the liner is in place, the technician is able to double check the placement of the repair and is capable of making any last-minute adjustments, giving the installer complete control of the installation process.

Connect to Compressed Air / Hot Water

Once in place, the bladder inside the liner is connected to hot water, compressed air, or both in order for the saturated epoxy liner to exothermically react and cure.

final inspection

Once cured, the bladder is deflated and removed from the system. A final CCTV inspection takes place to ensure the liner was installed correctly.

Why not just replace the pipes?

Pipe replacement has many disadvantages, which include the creation of a messy construction site, significant time to completion, and the fact that the new pipe is doomed to the same failures as the old pipe. NuFlow’s cured-in-place(CIPP) lining solutions are non-destructive, eco-friendly, non-invasive, cost-effective, and can be installed in a fraction of the time.

Less Invasive

You don’t have to destroy the property to fix the pipes. Lining minimizes damage to walls, floors and surrounding areas because lining is handled through cleanouts or other existing access points. If a sewer pipe is under concrete or pavement, there’s no need to jackhammer it up since our pipe lining technology slides right into the existing pipe.

Less Expensive

Rehabilitating sewer pipes using lining can cost half of what conventional pipe replacement does. There is little structural modification involved because there is no need to take out walls or tear up the street or lawn. Minimal exterior digging also reduces clean-up costs, as well as the labor costs needed to complete the job.

Faster

Typically lining takes about half the time of pipe replacement. Without the need to dig or spend time repairing walls, floors and ceilings, the procedure of pipe lining is more time efficient than complex conventional pipe replacement. And because lining is developed to solve the problem for the long-term, it helps prevent problems such as corrosion and leaks from reoccurring and reduces future inconvenience for property owners and managers.

Long Lasting

It’s faster, less invasive, and less expensive, but it is projected to last just as long. Our lining technologies are projected to last more than 50 years, about the same as you’d expect with conventional pipe replacement. You can get all the benefits of lining and still get the same life out of the pipes.

JOIN

TODAY!

Begin the path to new expertise, product offerings, and revenue streams. NuFlow technicians are highly-qualified educators and can offer the industry expertise, guidance, and resources to help you start installing state-of-the-art NuFlow products in no time.

Let's Get Started

"*" indicates required fields