The NuFlow Advantage

- Quality Assurance Tools and Equipment

- Cure Validation through Real-Time Data Collection & Analytics

- Condition Assessment and Site Evaluation Tools

- Comprehensive Training and Field Support

RECOMMENDED APPLICATIONS

- High pressure pipes such as water mains and sewer force mains

- Potable water pipes

- Hydronic heating & cooling

- Gas

BENEFITS

- Preservation of surface and underground infrastructure

- Minimal traffic disruption

- Low noise and dust pollution for neighborhood residents

- Protection of the environment due to CO2 emission reduction

- Extremely short turnaround times

- High-cost efficiency

- Restoration of the functionality of a pipeline system for decades to come

- Quality Assurance Tools and Equipment

- Cure Validation through Real-Time Data Collection & Analytics

- Condition Assessment and Site Evaluation Tools

- Comprehensive Training and Field Support

- High pressure pipes such as water mains and sewer force mains

- Potable water pipes

- Hydronic heating & cooling

- Gas

- Preservation of surface and underground infrastructure

- Minimal traffic disruption

- Low noise and dust pollution for neighborhood residents

- Protection of the environment due to CO2 emission reduction

- Extremely short turnaround times

- High-cost efficiency

- Restoration of the functionality of a pipeline system for decades to come

Pressurized CIPP

NuFlow Technologies, a leader in innovative pipe lining solutions, has partnered with Belgium-based NordiTube Technologies to bring their line of pressurized CIPP products to North America. This collaboration marks a significant advancement in the pipe lining industry, particularly in the realm of pressurized systems. Pressurized CIPP by NordiTube, a key offering in the pipe lining sector, structurally repairs any type of pressure pipe system with minimal disruption. This partnership underscores NuFlow's commitment to expanding and enhancing pipe lining technologies, providing North American customers with access to world-class pressurized CIPP solutions known for their efficiency and reliability.

Pressurized CIPP

Product Overview

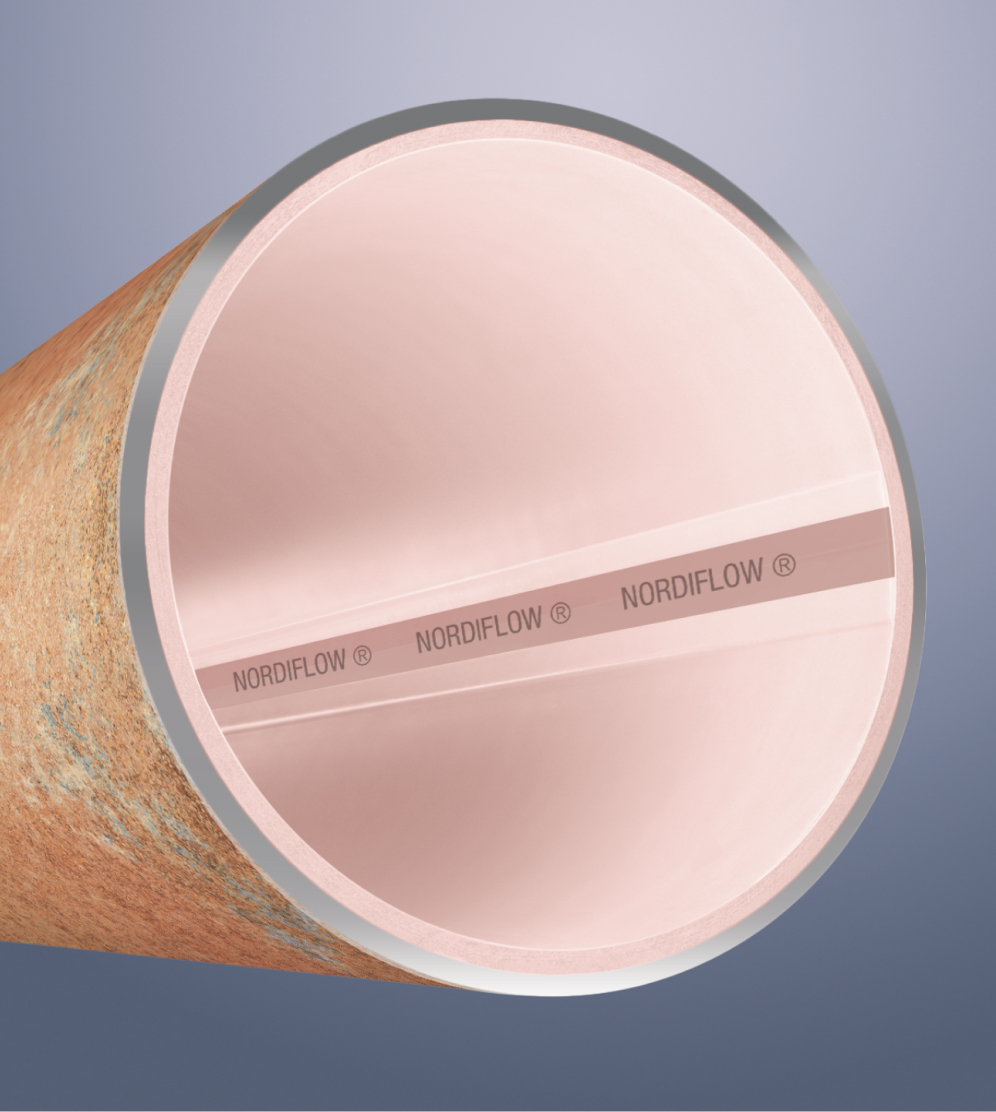

NORDIFLOW

The strong and independent pressure liner.

NORDIFLOW

The strong and independent pressure liner.

BENEFITS AT A GLANCE

- Liner can be designed as Class IV full-structural or Class III semi-structural

- Long term operating pressure PFA up to 232 psi (depending on diameter)

- Short term operating pressure PMA up to 435 psi (depending on diameter)

- Individual lengths and bends are possible

- Approved for potable water

NORDIWALL HT

The resistant liner for high-temperature pipes.

NORDIWALL HT

The resistant liner for high-temperature pipes.

BENEFITS AT A GLANCE

- Temperature resistance up to 140°C

- Excellent chemical resistance

- Good performance in bends

- Excellent adhesion behavior to resist pressure surge

- Felt liner coated with modified Polypropylene

- Class I: Corrosion protection

TUBETEX

The seamless textile pressure liner.

TUBETEX

The seamless textile pressure liner.

THE BENEFITS AT A GLANCE

- The liner is designed as Class II - interactive system relying on bonding to existing pipe

- Trenchless reopening of connecting laterals

- Long-term operation pressure PFA according to DVGW GW 327, W 330 - up to 232 psi for water - up to 435 psi for gas

- Seamless fabric hose - Individual lengths bends are possible

- Approved for potable water and gas

For Detailed Product Information download the NordiTube brochure.

TRENCHLESS REHABILITATION FOR PRESSURE PIPES POWERED By

NuFlow Technologies has partnered with ASOE Hose Manufacturing, Inc. to offer their line of pressurized pipe rehabilitation products throughout Europe.

The ASOE hose liner solution is non-structural pipe rehabilitation. There is no connection between the host pipe and the liner, so the liner works independently from the host pipe. The liner is somewhat rigid, and it will maintain its round shape inside the host pipes even without inside pressure or with little pressure from outside.

The basic installation procedure is straightforward - no resin, no impregnation, no curing necessary. Pull the liner into the host pipe and expand. The hose liner will then function as a leakage-free liner inside the host pipes. The hose liner is flexible and can easily be pulled through 45-degree or 90-degree bends with a 5D radius. Only coarse pipe cleaning is required before hose liner installations.

NuFlow's European Training Programme provide you with the training and local on-site support to ensure a successful and profitable pressure pipe lining project.

Product Overview

Pipe-in Liner W Series

Rehabilitating water mains and other water pipes with inside pressure at normal temperature.

Pipe-in Liner W Series

Rehabilitating water mains and other water pipes with inside pressure at normal temperature.

- Nominal ID of host pipes: 50mm (2 inches) - 1400mm (55 inches)

- Maximum length of each installation: up to 4000m (13,000ft)

- Maximum operating pressure: 1.0 - 4.0 Mpa (150psi-600psi)

- Maximum bursting pressure: 3.0 - 12.0 Mpa (450psi-1800psi)

- Installation mode: Pull in U-shape Liners

- Raw materials: High tenacity fabric reinforcement layer, abrasion-resistant PE cover, PE tube (NSF61 certified, Potable Water Safety approved by NHFPC of China)

- Service life duration: 50 years

Pipe-in Liner O Series

Rehabilitating oil pipes onshore or offshore.

Pipe-in Liner O Series

Rehabilitating oil pipes onshore or offshore.

- Nominal ID of host pipes: 50mm (2 inches) - 1400mm (55 inches)

- Maximum length of each installation: Up to 4000m (13,000ft)

- Maximum operating pressure: 1.0 - 4.0 Mpa (150psi-600psi)

- Maximum bursting pressure: 3.0-12.0 Mpa (450psi-1800psi)

- Installation mode: Pull in U-shape Liners

- Raw Materials: High tenacity fabric reinforcement layer, abrasion resistant PE cover, oil resistant PU tube or oil and heat-resistant PVDF tube (PVDF is relatively expensive)

- Service life duration: 40 years

Pipe-in Liner G Series

Rehabilitating gas pipes

Pipe-in Liner G Series

Rehabilitating gas pipes

- Nominal ID of host pipes: 50mm (2 inches) - 1400mm (55 inches)

- Maximum length of each installation: Up to 4000m (13,000ft)

- Maximum operating pressure: 1.0 - 4.0 Mpa (150psi-600psi)

- Maximum bursting pressure: 3.0-12.0 Mpa

- Installation mode: Pull in U-shape Liners

- Raw Materials: High tenacity fabric reinforcement layer, abrasion resistant PE cover, airtight PU tube

- Service life duration: 40 years

Pipe-in Liner H Series

Rehabilitating hot water pipes in municipal heat systems, since it can resist temperatures up to 95° C (203° F).

Pipe-in Liner H Series

Rehabilitating hot water pipes in municipal heat systems, since it can resist temperatures up to 95° C (203° F).

- Nominal ID of host pipes: 50mm (2 inches) - 1400mm (55 inches)

- Maximum length of each installation: Up to 4000m (13,000ft)

- Maximum operating pressure: 1.0 - 4.0 Mpa (150psi-600psi)

- Maximum bursting pressure: 3.0-12.0 Mpa (450psi-1800psi)

- Installation mode: Pull in U-shape Liners

- Raw Materials: High tenacity fabric reinforcement layer, heat resistant PUX cover, heat-resistant PUX tube

- Service life duration: 40 years

For Detailed Product Information download the ASOE brochure.

JOIN

TODAY!

Begin the path to new expertise, product offerings, and revenue streams. NuFlow technicians are highly-qualified educators and can offer the industry expertise, guidance, and resources to help you start installing state-of-the-art NuFlow products in no time.

Let's Get Started

"*" indicates required fields