Pipe lining is a way to restore the pipe from corrosion, leaks, or cracks from roots. It’s a four step process and essentially is putting a pipe within a pipe. Lining is cost efficient and less disruptive in comparison to replacing the entire pipe. Pipe lining also increases the life span of a piping system, preserves the building structure, landscape, and causes little to no destruction to the property.

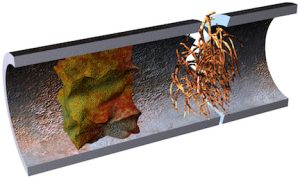

Two common types of pipe failures are pipe corrosion and tree roots growing into the pipe. You may be wondering how does a cast iron pipe corrode? It comes down chemistry. Four elements together lead to the deterioration of pipes: oxygen, metal, water, and minerals which are chemicals. This chemical reaction causes a build up called scaling, which is a mound of corrosion where minerals such as chloride and sulphur to into acids that eat away at the pipe.

Water that eventually runs through drain pipes is often treated for consumption by chlorine (a type of chemical) and if that chlorine is highly concentrated that will corrode pipes over time. Trees are another cause of pipe failures - trees grow their root systems into pipes causing cracks. Why? Trees are always looking for water to survive and drain pipes are that perfect source of water.

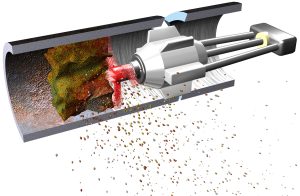

The next step in the lining process is to clean the pipe so that the CIPP liner will adhere to the host pipe. Pipes are cleaned with mechanical cutters that can remove scale buildup and roots.

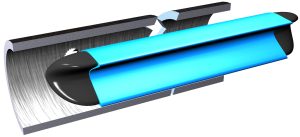

Once the pipe is cleaned the technicians saturate a felt liner with a two part epoxy. They score (cut) the outside of the liner so that it will adhere to the inside of the pipe. No water will be able to get in-between the liner and the inside of the pipe. The liner is then pulled through the pipe and the rubber bladder inside the felt is expanded to allow epoxy liner to cure, adhering it to the host pipe.

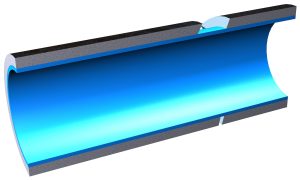

Once the CIPP liner hardens to the pipe, the rubber bladder is deflated and removed, leaving behind a better than new pipe within the existing system. Why lining works is because the lining separates the original pipe that is susceptible to failure from the material flowing through it.