Commercial

A NuFlow Certified Contractor performed a camera inspection and cleaned each section of the pipe network. In some areas the pipes were so badly corroded that it resulted in a complete void in the bottom half of the pipe. Other areas were not as severe, but still showed signs of deterioration with potential for future problems. They opted to line the entire system to repair the existing damage and prevent future pipe failure.

Over time, ABS drain lines can succumb to shifting, which causes structural fractures and offsets. Conventional replacement of ABS lines can be very costly, especially when located beneath structural slabs and within facilities that have daily operational businesses. The solution to this in many cases is NuFlow’s patented structural in-situ trenchless solutions. This 12-story, […]

Neither flooding, nor backups, nor sewer smells stays these couriers from the swift completion of their appointed rounds. Learn how pipe lining was the clear solution for this Nevada post office. Mail delivery is a non-stop 24-hour operation. After decades of round the clock production, a mail sorting facility in Nevada needed some major repairs. […]

During a renovation for this mall, the customer wanted to repair a horizontal grease line that services the restaurant kitchens in the food court. Part of the 4” diameter cast iron grease line goes through a 2ft thick concrete wall. They decided to use NuFlow’s non-invasive pipe lining instead of the pipe replacement. The NuFlow technicians utilized several existing access points to clean and retrofit this horizontal grease line. The job was completed in one day, as opposed to the weeks of work a traditional repipe would have taken.

Over time, all drain systems develop problems and require attention. Replacing those pipes comes with the need to dig through floors and foundations or to cut through walls to access the pipes, which can be very time-consuming and costly. However, this can be avoided with the NuFlow’s patented NuDrain process, an in-situ trenchless solution for […]

This busy office tower could not afford to have leaking pipes hold it back from normal operations. Repairing cracked pipes above the bank tellers’ desks would be disruptive, messy and an inconvenience for customers. NuFlow’s trenchless solutions are beneficial because 101 West Broadway did not have to stop normal operations for an imperative pipe lining […]

Over time, all drain systems develop problems, begin to fail and require attention. Replacing those pipes comes with the need to dig through floors and foundations or to cut through walls to access the pipes, which can be very time-consuming, costly and disruptive. However, this can be avoided with the patented NuFlow process, an in-situ […]

After spending nearly a decade using traditional fixes to prevent an aged wet vent pipe from cracking and releasing stenches, this customer decided to invest in a long-term solution. Although an inversion pipe lining company told the building engineer that the failing pipe system could not be rehabilitated without causing a great deal of destruction […]

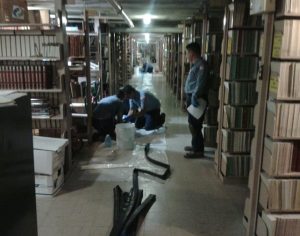

Downtown Library: Sanitary Drain System Rehabilitation Situation: This 5-story, historic, public library, located in a heavily populated urban area, experienced sanitary sewer line failures. The diameters of these cast iron pipes are 2″ to 4″. Old age caused these pipes to leak. Out of fear, the library looked for long-term solutions to protect the books. […]

Grocery Store: Grease Drain Line Rehabilitation Location: Tampa, Florida Situation: After this food store managing company experienced a messy and costly repipe for a tenant, it looked for nondestructive options to rehabilitate another tenant’s failing drain lines. These grease lines, located under concrete slab in the grocery store’s deli, had completely eroded bottoms. Solution: The […]